Leading Professional 3D Printing Service in Singapore

Offering high-quality 3D printing services in Singapore, we utilize advanced industrial technologies like SLA, SLS, SLM, FDM, and MJF to meet diverse manufacturing needs. From prototyping and product development to custom manufacturing, our solutions cater to industries such as aerospace, consumer goods, education, and research. With a focus on precision, durability, and efficiency, our 3D printing services ensure every project meets the highest standards. By combining cutting-edge technology with high-quality materials, we bring ideas to life with exceptional accuracy and reliability, making 3D printing services an essential tool for innovation and production.

Why Choose 3D Specialist?

Our commitment to excellence extends beyond just printing. We provide personalized support and guidance, helping you optimize your designs for the best possible results. Whether you need a single prototype or a full production run, our advanced 3D printing capabilities and exceptional customer service guarantee a seamless and rewarding experience. At 3D Specialist, we believe in pushing the boundaries of innovation and empowering our clients to achieve their goals through cutting-edge 3D printing technology.

Get A QuoteTechnologies we use

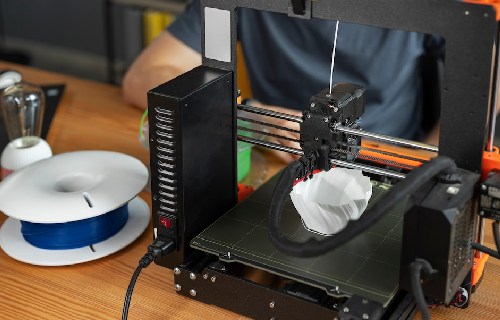

FDM 3D Printing Service

Fused Deposition Modeling (FDM) is one of the most widely used 3D printing services, known for its versatility in producing functional thermoplastic parts through an extrusion-based process. By melting and depositing thermoplastic material layer by layer, FDM creates strong and durable components suitable for various applications, from prototyping to low-volume production. While the process naturally results in visible layer lines and support marks, production-grade FDM offers a broad material selection, including ABS, PC, PC-ABS, ASA, Nylon, Carbon Composites, Ultem, and Pekk, making it ideal for demanding mechanical applications. Despite some surface texture limitations, this 3D printing service remains a reliable and cost-effective choice for manufacturing robust and high-performance parts, with post-processing techniques available to enhance their final appearance and functionality.

SLA 3D Printing Service

Stereolithography (SLA) is a high-resolution 3D printing service that uses a laser to cure liquid resin layer by layer, producing highly detailed parts with smooth surfaces and minimal visible layer lines. Capable of achieving resolutions as fine as 20 microns, this process is ideal for creating intricate concept models and prototypes that require superior accuracy and surface finish. SLA supports a wide range of materials, including rigid opaque, transparent, and flexible resins, allowing for multi-material printing and overmold simulations. Additionally, this 3D printing service enables the production of complex geometries in a single operation, significantly reducing build time while maintaining precision and design flexibility.

SLM 3D Printing Service

Selective Laser Melting (SLM) is a high-precision 3D printing service that utilizes a powerful laser to fuse metal powder layer by layer, producing strong and complex metal parts with exceptional accuracy. Unlike traditional metal machining, SLM eliminates the need for extensive tooling, allowing for greater design flexibility and intricate geometries. This advanced 3D printing service is ideal for manufacturing industrial-grade metal components, enabling rapid production of high-quality, end-use parts within days, making it a preferred choice for industries requiring precision and durability.

MJF 3D Printing Service

Multi Jet Fusion (MJF) is an advanced 3D printing service, designed for producing functional plastic parts with exceptional precision and isotropic mechanical properties. Unlike SLS, MJF uses fusing and detailing agents combined with heat and pressure to create high-quality, watertight parts without the need for support structures. This 3D printing service is ideal for detailed prototyping and low-volume production, delivering excellent surface finish and dimensional accuracy. Highly scalable, MJF enables cost-effective manufacturing of over 1,000 end-use parts within days, making it a reliable choice for industries requiring efficient and high-performance production.

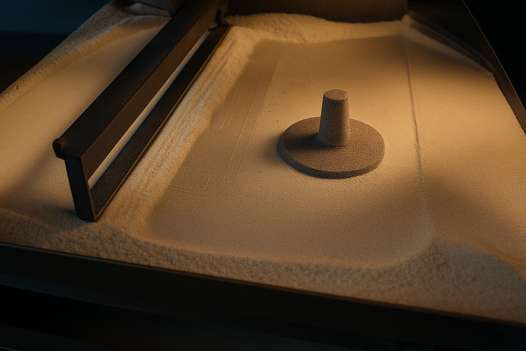

SLS 3D Printing Service

Selective Laser Sintering (SLS) is an advanced 3D printing service that utilizes a high-powered laser to sinter thermoplastic powder layer by layer, creating strong and durable parts without the need for support structures. Unlike other methods like FDM, SLA, or MJF, SLS transforms powder directly into a solid state, ensuring excellent mechanical properties such as high strength and heat resistance. This 3D printing service is ideal for industrial and aerospace applications, offering a high degree of design freedom and the ability to produce intricate, functional parts. Additionally, SLS is highly scalable, enabling the efficient production of over 1,000 high-quality end-use parts within days, with options for post-processing to enhance surface finish and texture.

3D printed parts

showcase of unlimited possibilities

Binder Jetting

Copper Bus Bars

Carbon Fiber Kit

Steel Whistle

Tube Bending

Palmer Foundry

Brackets

Hybrid Gripper

How it works

1. Fill Up a Form

Provide your contact information and wait for our experts to reach out to you.

2. Connect with our Experts

Get in touch with our 3D Specialist and have a conversation about the specific parts you're interested in.

3. Get Your Desired Services

Once we've discussed your needs, our team will work diligently to ensure your parts are delivered to you quickly.

Industries we serve

Our Services

Explore our website to learn more about our comprehensive suite of services and cutting-edge capabilities. Join us on the journey to revolutionize manufacturing and unlock new possibilities for your business with Advance Manufacturing Solutions.

Ready to Transform Your Ideas?

Get A QuoteContact us today to discover how our 3D printing consultation services can help you innovate, enhance efficiency, and achieve your manufacturing goals. Let us guide you on the path to success with cutting-edge 3D printing solutions.